A Seamless Workflow for the Design and Fabrication of Multimaterial Soft Actuators

This research earned the IEEE-CASE Best Application Paper Award at the 2021 CASE Conference in Lyon, France!

Highlights

- A novel software workflow for exploration of the complex design space of pneumatic soft actuators

- Prioritization of seamless connectivity between design and evaluation phases: geometry and material specification, visualization, simulation, and fabrication

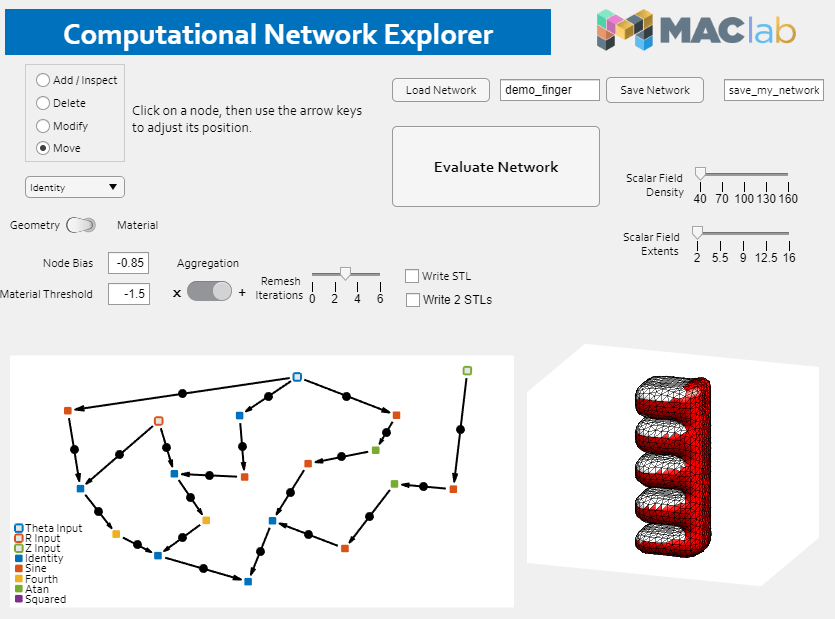

- A graphical user interface for interactive exploration of computational network representations of implicit geometry functions

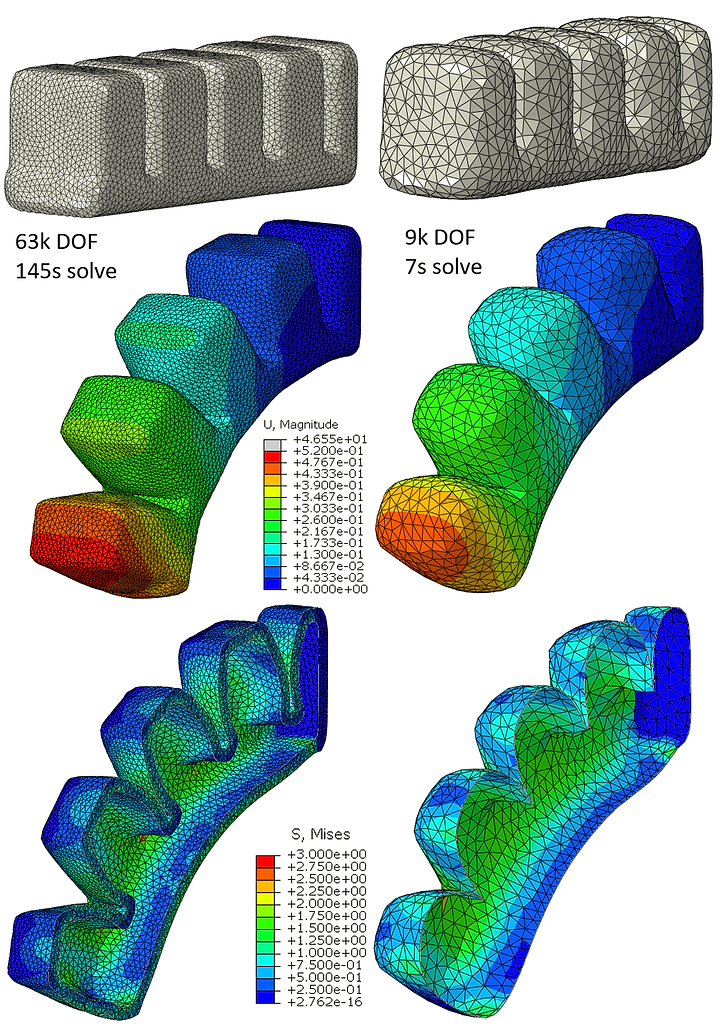

- Automated generation of simulation input files for one-click execution of nonlinear FEA evaluation of candidate designs

A Seamless Workflow

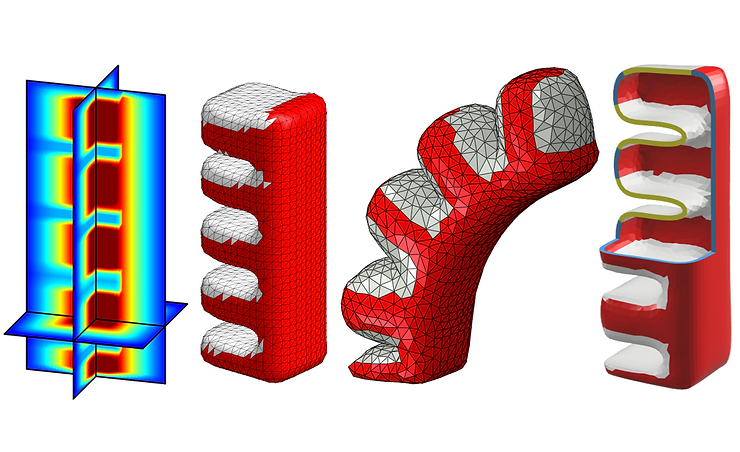

- Multimaterial soft actuators at progressive stages of development in our workflow. From left: signed distance function geometry description; surface triangulation and material assignment; simulated deformation during actuation; preparation for additive manufacturing; 3D-printed actuator.

An Interactive Design Tool

Our GUI-based, interactive design tool lowers barriers to multimaterial soft actuator design

Automatic generation of FEA studies using shell and volumetric elements. Shell element offer drastically reduced computation cost at the expense of lower resolution and accuracy.

Fabricated Actuators

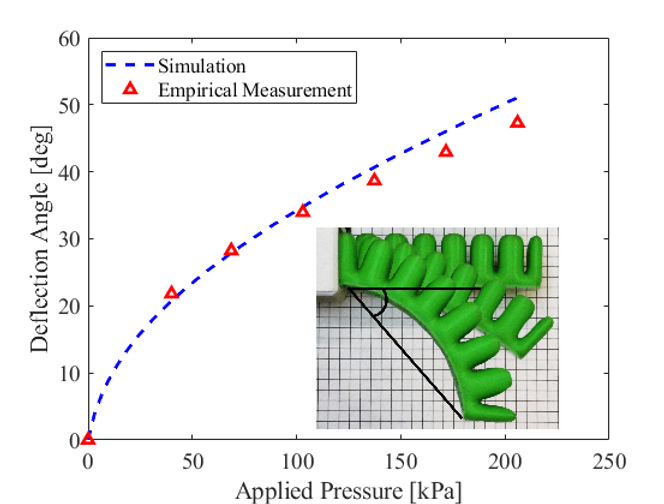

Actuators designed in our workflow can be fabricated by additive manufacturing and actuated using pressurized fluid.